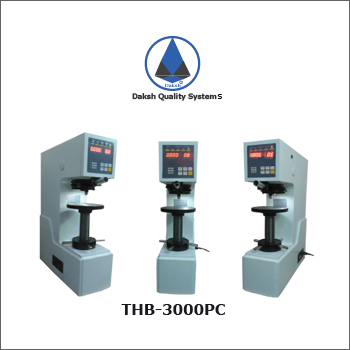

Industrial Computerised Brinell Hardness Testing Machine

45000 INR/Piece

Product Details:

- Equipment Type Brinell Hardness Testing Machine

- Response Time Instantaneous

- Application Industrial Metal Hardness Measurement

- Temperature 10C to 45C

- Features Computerized control, Automatic loading/unloading, Data logging, Touchscreen compatible, Motorized system, Printer

- Test Range 8-650 HBW

- Interface Type USB, RS232

- Click to view more

X

Industrial Computerised Brinell Hardness Testing Machine Price And Quantity

- 45000 INR/Piece

- 1 Piece

- Automatic and manual supported

- Direct reading through camera and software

- Load cell based, motorized with feedback control

- Hardened steel / Tungsten carbide ball, 2.5/5/10 mm

- Emergency stop, Overload protection, Operator warning

- Windows-based industrial software

- English (Multi-language optional)

- PC-based storage, upgradable

- LED illumination for sample viewing

- High resolution CCD camera, USB interface

- Digital, Graphical report, USB Export, Printing

- User Selectable (62.5 kgf, 187.5 kgf, 250 kgf, 500 kgf, 750 kgf, 1000 kgf, 1500 kgf, 3000 kgf)

Industrial Computerised Brinell Hardness Testing Machine Product Specifications

- Brinell Hardness Testing Machine

- 10C to 45C

- Industrial Metal Hardness Measurement

- Instantaneous

- Approx. 350 kg

- Computerized control, Automatic loading/unloading, Data logging, Touchscreen compatible, Motorized system, Printer

- 8-650 HBW

- Computer Display (LCD/Monitor)

- USB, RS232

- 0.1 HBW

- Complies to IS:2281, ISO 6506, BS240, ASTM-E10 standards

- 230V AC

- Up to 90% RH (non-condensing)

- USB Interface

- 3000 kgf Max.

- Computerised / Automatic

- Hardness Testing of Steels and Alloys

- 50 Hz

- Single or multiple (one at a time)

- 230V AC, 50Hz, Single Phase

- 250 mm max

- Brinell (HBW)

- 10 mm to 250 mm height

- Adjustable, up to 0.5 mm/sec

- Automatic

- 150 mm max

- 53000 HBW

- 250 mm specimen

- Bench / Table Top

- Automatic and manual supported

- Direct reading through camera and software

- Load cell based, motorized with feedback control

- Hardened steel / Tungsten carbide ball, 2.5/5/10 mm

- Emergency stop, Overload protection, Operator warning

- Windows-based industrial software

- English (Multi-language optional)

- PC-based storage, upgradable

- LED illumination for sample viewing

- High resolution CCD camera, USB interface

- Digital, Graphical report, USB Export, Printing

- User Selectable (62.5 kgf, 187.5 kgf, 250 kgf, 500 kgf, 750 kgf, 1000 kgf, 1500 kgf, 3000 kgf)

Industrial Computerised Brinell Hardness Testing Machine Trade Information

- 15 Piece Per Month

- 3-4 Days

Product Description

Capitalise on monumental advances with our Industrial Computerised Brinell Hardness Testing Machine. Designed for dominant performance in metal hardness measurement, this ravishing equipment combines precision with computerised control. Featuring hardened steel/tungsten carbide ball indenters, load cell-based motorized force application, and user-selectable test loads, it ensures instant digital results and graphical reporting. Add to Cart for upgradable PC-based data storage, Windows software compatibility, and enhanced safety features. Advance Purchase options let you secure a machine that meets global standards and offers unrivaled reliability for industrial usage.

Competitive Edge and Advanced Features

Our Brinell Hardness Testing Machine stands out for its computerised/automatic controls, digital outputs, and direct camera/software measurements. Users benefit from touchscreen compatibility, emergency stop, dominant overload protection, and user-selectable load settings. Extra features like USB export, data logging, PC-based storage, and LED sample illumination capitalise on advanced industrial needs. Accuracy and resolution conform to IS:2281, ISO 6506, BS240, ASTM-E10 standards, offering superior performance and reliability in hardness testing applications.

Export Markets, Samples, and Certifications

We supply this innovative machine to multiple high-value export markets, charging competitive rates for market-leading reliability. Sample units are available upon request, enabling buyers to assess ravishing features upfront. Our product is certified to industry standards, ensuring market value and consistent performance. As a trusted exporter, manufacturer, and service provider from India, we supply globally and maintain compliance with international certifications. Swift supply and deployment further enhance our dominant presence in the global market.

Competitive Edge and Advanced Features

Our Brinell Hardness Testing Machine stands out for its computerised/automatic controls, digital outputs, and direct camera/software measurements. Users benefit from touchscreen compatibility, emergency stop, dominant overload protection, and user-selectable load settings. Extra features like USB export, data logging, PC-based storage, and LED sample illumination capitalise on advanced industrial needs. Accuracy and resolution conform to IS:2281, ISO 6506, BS240, ASTM-E10 standards, offering superior performance and reliability in hardness testing applications.

Export Markets, Samples, and Certifications

We supply this innovative machine to multiple high-value export markets, charging competitive rates for market-leading reliability. Sample units are available upon request, enabling buyers to assess ravishing features upfront. Our product is certified to industry standards, ensuring market value and consistent performance. As a trusted exporter, manufacturer, and service provider from India, we supply globally and maintain compliance with international certifications. Swift supply and deployment further enhance our dominant presence in the global market.

FAQ's of Industrial Computerised Brinell Hardness Testing Machine:

Q: How does the computerized Brinell hardness testing process work?

A: The machine applies a user-selectable load via a motorized, load cell-based system, then measures indentation with a high-resolution camera. Results are processed automatically and displayed instantly.Q: What sizes and types of indenters are available for this machine?

A: The machine supports hardened steel and tungsten carbide ball indenters in 2.5, 5, and 10 mm sizes, suitable for varied metals and testing requirements.Q: When should I use the emergency stop or overload protection features?

A: Use these features during unexpected situations, such as system overloads or operational errors, to ensure safety and protect both operator and equipment.Q: Where are the test results stored and how can I export them?

A: Test results are digitally stored on a PC-based system and can be exported via USB, printed, or used in graphical reports for further analysis.Q: What are the main benefits of automated loading/unloading and touchscreen compatibility?

A: Automated processes and touchscreen controls streamline operation, minimise human error, increase efficiency, and make hardness testing user-friendly for industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free