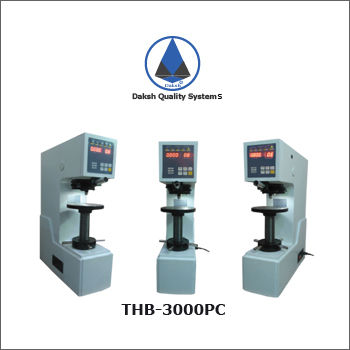

Computerized Brinell Hardness Tester

290000.0 INR/Piece

Product Details:

- Specimen Size Up to 250 mm height

- Interface Type USB

- Response Time Immediate/Software Dependent

- Port Size USB 2.0

- Power Supply 230 V AC, 50 Hz

- Application Brinell Hardness Testing of Metals & Alloys

- Resolution 0.01 HBW

- Click to view more

X

Computerized Brinell Hardness Tester Price And Quantity

- 1 Piece

- 290000.0 INR/Piece

- High Resolution CCD Camera for Impression Measurement

- Automatic Brinell Impression Measurement, Data Storage, Report Generation

- LED Illumination for Impression Area

- Export in Excel/PDF/Print Direct

- 5-60 sec, Programmable

- 500 kgf

- Integrated Emergency Stop and Limit Switches

- 10mm Hardened Steel Ball

- Heavy Duty Cast Iron for Stability

- ± 0.5%

- User Programmable, 500/750/1000/1500/3000 kgf

- 165 mm

- Windows 7/8/10

Computerized Brinell Hardness Tester Product Specifications

- Up to 3000 kgf

- USB

- Up to 250 mm height

- 0.01 HBW

- Computer Controlled

- Approx. 150 mm

- 100 mm

- Immediate/Software Dependent

- USB 2.0

- 230 V AC, 50 Hz

- Brinell Hardness Testing of Metals & Alloys

- 10C 35C

- Laboratory/Industrial

- 0.5 1 mm/sec

- Automatic

- 230 V AC

- 8 650 HBW

- Approx. 200 kg

- 50 Hz

- Digital on Computer Screen

- 85% RH

- Computerized Brinell Hardness Tester

- Automatic Loading/Unloading, Digital Readout, PC Connectivity

- 1% of Displayed Value

- Single/Multiple via Software

- 8 650 HBW

- Bench Top

- 250 mm

- 8 650 HBW

- High Resolution CCD Camera for Impression Measurement

- Automatic Brinell Impression Measurement, Data Storage, Report Generation

- LED Illumination for Impression Area

- Export in Excel/PDF/Print Direct

- 5-60 sec, Programmable

- 500 kgf

- Integrated Emergency Stop and Limit Switches

- 10mm Hardened Steel Ball

- Heavy Duty Cast Iron for Stability

- ± 0.5%

- User Programmable, 500/750/1000/1500/3000 kgf

- 165 mm

- Windows 7/8/10

Computerized Brinell Hardness Tester Trade Information

- 15 Piece Per Month

- 3-4 Days

Product Description

Product details

| Depth of Throat | 200 mm |

| Drive Motor | 0.33 HP |

| Machine Height | 1230 mm (approx) |

| Max Test Height | 360 mm (approx) |

| Power Supply | 3 Phase 400-440 V, 50 Hz AC |

| Test Loads | 500,750,1000, & 3000 kgf |

| Size | 390 X 910 mm (approx) |

| Model Name/Number | DB 3000 PC |

Robust and User-Friendly Design

Constructed from heavy-duty cast iron, this hardness tester provides exceptional stability during operation. Its user-programmable features-such as selectable test forces and dwell times-allow flexible adaptation to a variety of materials. Integrated safety interlocks, like emergency stop and limit switches, enhance operational safety for users in industrial and laboratory settings alike.

Advanced Automatic Measurement and Reporting

Equipped with a high-resolution CCD camera and LED illumination, the device ensures precise, automatic measurement of Brinell impressions. The intuitive software offers real-time digital readout, data storage, and seamless report generation in Excel or PDF formats. This comprehensive suite of features streamlines testing processes and data management, reducing human error and boosting efficiency.

FAQ's of Computerized Brinell Hardness Tester:

Q: How does the Computerized Brinell Hardness Tester ensure accurate hardness measurement?

A: The instrument uses a 10mm hardened steel ball indenter and programmable test forces ranging from 500 to 3000 kgf. The high-resolution CCD camera and advanced software automatically measure Brinell impressions with a repeatability of 0.5% and accuracy within 1% of the displayed value, minimizing user intervention and error.Q: What types of specimens can be tested and what is the maximum specimen size?

A: The tester is suitable for metals and alloys, accommodating specimens up to 250 mm in height and up to 165 mm in width. Single or multiple specimens can be tested via software, making it ideal for both laboratory and industrial applications.Q: When should I use the programmable dwell time feature?

A: Programmable dwell times (from 5 to 60 seconds) allow you to tailor the test to the material being examined. Adjusting dwell time ensures proper material deformation and more consistent, reliable Brinell hardness readings across a variety of metal and alloy types.Q: Where can I store and export the hardness test data?

A: Test data can be saved directly to the connected computer via the specialized software. Results and reports are easily exported in Excel or PDF formats, or printed directly for documentation or quality control purposes.Q: What is the process for performing a Brinell hardness test with this equipment?

A: Place your specimen on the bed, select the desired test force and dwell time through the software, and initiate the automatic test. The machine will load/unload automatically, measure the impression using the CCD camera, compute the hardness, and display it digitally. Results can be stored or exported as needed.Q: How does this tester benefit industrial or laboratory environments?

A: Automation streamlines the entire measurement process, enhancing throughput and consistency. Digital integration allows for easy data analysis and report generation, saving time and improving traceability, which is vital for quality control and research.Q: What are the usage safety features of the Brinell Hardness Tester?

A: The tester incorporates integrated emergency stop and limit switches to immediately halt operations and prevent damages or accidents, further supported by a user-friendly design for safe handling in laboratory or industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free