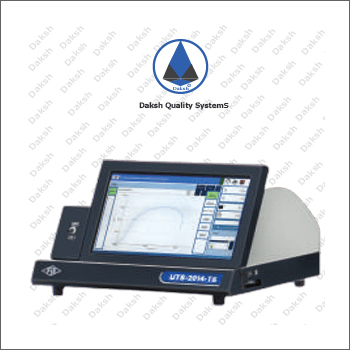

Pro Broach Automatic Broaching Machine

45000 INR/Piece

Product Details:

- Gas Pressure 0.5 - 0.8 MPa

- Test Range 15 - 80 mm

- Power Supply 220 V / 50 Hz

- Max Height 1600 mm

- Hardness Up to 60 HRC

- Features Automatic feed, digital control, robust structure, emergency stop

- Resolution 0.001 mm

- Click to view more

X

Pro Broach Automatic Broaching Machine Price And Quantity

- 45000 INR/Piece

- 1 Piece

- Overload Protection, Safety Guard

- 2.2 kW

- Automatic Lubrication

- Steel, Stainless Steel, Copper, Aluminium

- <70 dB

- Onsite/Remote

Pro Broach Automatic Broaching Machine Product Specifications

- 450 mm

- Digital

- custom as per requirements

- 40% - 80% RH

- 1/2 inch

- 1 (customizable options available)

- Automatic

- 15 - 80 mm

- Broaching Machine

- 0.01 mm

- Automatic

- 320 mm

- 5C - 40C

- 220 V AC

- Precision Component Broaching/Manufacturing

- Touchscreen

- 0.001 mm

- Automatic feed, digital control, robust structure, emergency stop

- 50 Hz

- 1 s

- Floor Mounted

- 5-10 pcs/hour

- Internal/External Broaching

- 100-120 mm/min

- 220 V / 50 Hz

- 15 - 80 mm

- 850 kg

- 0.5 - 0.8 MPa

- 1600 mm

- Up to 60 HRC

- Overload Protection, Safety Guard

- 2.2 kW

- Automatic Lubrication

- Steel, Stainless Steel, Copper, Aluminium

- <70 dB

- Onsite/Remote

Pro Broach Automatic Broaching Machine Trade Information

- 15 Piece Per Month

- 3-4 Days

Product Description

Experience the ephemeral excellence of the Pro Broach Automatic Broaching Machine-a remarked choice for outstanding broaching precision. This gorgeous equipment seamlessly broaches steel, stainless steel, copper, and aluminium, powered by a robust 2.2 kW spindle. With automatic lubrication and advanced overload protection, every operation is secure and efficient. Enjoy digital control, automatic feed, and a remarkable accuracy of 0.01 mm. For a limited time, access exclusive discounts. Designed for precision component manufacturing, it serves as a stellar investment for manufacturers seeking reliability, safety, and exceptional performance.

Application Method & Area of Use

The Pro Broach Automatic Broaching Machine is primarily used for internal and external broaching applications in precision component manufacturing. Thanks to its automated control and digital touchscreen interface, users can implement precise material removal on varied metals. Suitable for high-accuracy production in automotive, aerospace, or machinery sectors, this equipment excels in environments demanding outstanding dimensional control and repeatable results.

Packaging, Samples & Export Markets

Each Pro Broach machine is carefully handed over to clients, packed using robust materials to ensure safe transit. Sample policies are flexible to help you assess quality and operational standards. Offered at the lowest price rates, this machinery is exported to global markets, with a strong presence in Asia, Europe, and the Americas. Dedicated service support guarantees you receive maximum value, whether as a manufacturer or supplier.

Application Method & Area of Use

The Pro Broach Automatic Broaching Machine is primarily used for internal and external broaching applications in precision component manufacturing. Thanks to its automated control and digital touchscreen interface, users can implement precise material removal on varied metals. Suitable for high-accuracy production in automotive, aerospace, or machinery sectors, this equipment excels in environments demanding outstanding dimensional control and repeatable results.

Packaging, Samples & Export Markets

Each Pro Broach machine is carefully handed over to clients, packed using robust materials to ensure safe transit. Sample policies are flexible to help you assess quality and operational standards. Offered at the lowest price rates, this machinery is exported to global markets, with a strong presence in Asia, Europe, and the Americas. Dedicated service support guarantees you receive maximum value, whether as a manufacturer or supplier.

FAQ's of Pro Broach Automatic Broaching Machine:

Q: How does the Pro Broach Automatic Broaching Machine ensure user safety during operation?

A: The machine includes advanced safety features such as overload protection and a safety guard, which minimize operational risks and protect both the operator and the equipment during use.Q: What materials can the Pro Broach machine broach?

A: It is compatible with a wide range of metals, including steel, stainless steel, copper, and aluminium, making it versatile for various manufacturing requirements.Q: Where can this broaching machine be used?

A: The machine is ideal for use in industries like automotive, aerospace, precision engineering, and any sector needing high-accuracy broaching of internal or external components.Q: What is the process for accessing service support for the machine?

A: Service support is available both onsite and remotely. You can contact the manufacturer directly for maintenance, troubleshooting, or operational guidance, ensuring that your machinery remains in optimal condition.Q: What benefit does the automatic lubrication system offer?

A: Automatic lubrication enhances operational efficiency by reducing manual maintenance, maintaining optimal cooling, and ensuring longevity for key machine parts during high-frequency usage.Q: How can specimen size be customized?

A: Specimen size is customizable according to your specific broaching requirements. Discuss your needs with the manufacturer for tailored solutions that suit your production specifications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free