Metallurgical Microscope Software

125000 INR/Piece

Product Details:

- Compatible System PC/Desktop/Laptop with minimum 4GB RAM

- Security Features Software Key or Login Protected Access

- Interface Type USB 2.0 / USB 3.0, Compatible with Camera Ports

- Capacity (Person) Single User License (multi-user optional)

- Language Support English (Others on demand)

- Support System Windows 7, Windows 8, Windows 10 (32/64-bit)

- Usage Industrial Laboratory, Educational Institutions

- Click to view more

X

Metallurgical Microscope Software Price And Quantity

- 125000 INR/Piece

- 1 Piece

- Intel Core i3 Processor, 4GB RAM, 500MB Free Disk Space

- Direct Export to Excel, Print, Email

- Free Updates for 1 Year

- Automatic report export (PDF/Excel/Word)

- Text, Arrow, Shapes, Color Coding

- Supports HD & Full HD Camera Inputs

- BMP, JPG, TIF, PNG, GIF

- Length, Area, Angle, Perimeter, Circle, Polygon, Grain Size ASTM

- Plug & Play with Most Metallurgical Microscopes

- Software-based, Multipoint Calibration Facility

- Project and Sample Management with Search Function

- Dongle/Code-based; Perpetual/Annual subscription

Metallurgical Microscope Software Product Specifications

- PC/Desktop/Laptop with minimum 4GB RAM

- Software Key or Login Protected Access

- USB 2.0 / USB 3.0, Compatible with Camera Ports

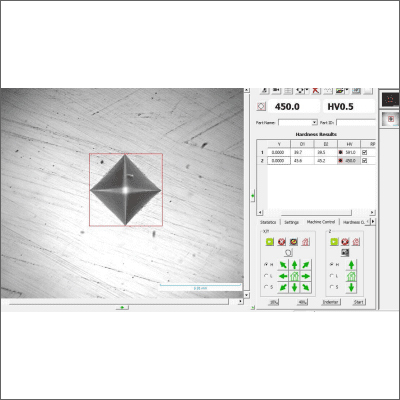

- Image Analysis Software for Metallurgical Microscopy

- Single User License (multi-user optional)

- Windows 7, Windows 8, Windows 10 (32/64-bit)

- Industrial Laboratory, Educational Institutions

- English (Others on demand)

- Metallurgical Analysis, Grain Size Measurement, Microstructure Observation

- Intel Core i3 Processor, 4GB RAM, 500MB Free Disk Space

- Direct Export to Excel, Print, Email

- Free Updates for 1 Year

- Automatic report export (PDF/Excel/Word)

- Text, Arrow, Shapes, Color Coding

- Supports HD & Full HD Camera Inputs

- BMP, JPG, TIF, PNG, GIF

- Length, Area, Angle, Perimeter, Circle, Polygon, Grain Size ASTM

- Plug & Play with Most Metallurgical Microscopes

- Software-based, Multipoint Calibration Facility

- Project and Sample Management with Search Function

- Dongle/Code-based; Perpetual/Annual subscription

Metallurgical Microscope Software Trade Information

- 15 Piece Per Month

- 3-4 Days

Product Description

Discover a transcendent deal on our top-ranking Metallurgical Microscope Software, purpose-built for professionals seeking blue-ribbon performance in industrial laboratories and educational institutions alike. Unlock instant savings with hot deals available for both dongle and code-based licenses, paired with robust support for BMP, JPG, TIF, PNG, and GIF images. Experience seamless HD and Full HD camera integration, multipoint software calibration, and advanced annotation and measurement tools. Automatic report generation and direct exporting capabilities empower your research. Enjoy free updates for one year and effortless plug & play with most metallurgical microscopes.

Versatile Applications and Surface Utility

Excelling in metallurgical analysis, our software extends its capabilities to grain size measurement, microstructure observation, and surface morphology exploration. It efficiently operates across various sample surfaces, including metals, alloys, ceramics, and composites. Common application areas cover academic research centers, industrial QC labs, manufacturing units, and metallurgical R&D. The software's adaptability ensures precise results in any environment requiring detailed image analysis, reinforcing its status as an indispensable laboratory tool.

Packaging Details, Delivery & Sample Supply

Our Metallurgical Microscope Software is delivered in secure, tamper-proof packaging to ensure integrity during shipment. FOB Port options include multiple major ports across India to facilitate international supply. Samples are available upon request for a nominal charge, so you can evaluate the product before full-scale procurement. Each purchase is supplied with comprehensive installation support and digital resources, offering ease of deployment and optimal user convenience from the first use.

Versatile Applications and Surface Utility

Excelling in metallurgical analysis, our software extends its capabilities to grain size measurement, microstructure observation, and surface morphology exploration. It efficiently operates across various sample surfaces, including metals, alloys, ceramics, and composites. Common application areas cover academic research centers, industrial QC labs, manufacturing units, and metallurgical R&D. The software's adaptability ensures precise results in any environment requiring detailed image analysis, reinforcing its status as an indispensable laboratory tool.

Packaging Details, Delivery & Sample Supply

Our Metallurgical Microscope Software is delivered in secure, tamper-proof packaging to ensure integrity during shipment. FOB Port options include multiple major ports across India to facilitate international supply. Samples are available upon request for a nominal charge, so you can evaluate the product before full-scale procurement. Each purchase is supplied with comprehensive installation support and digital resources, offering ease of deployment and optimal user convenience from the first use.

FAQ's of Metallurgical Microscope Software:

Q: How do I integrate the software with my existing metallurgical microscope?

A: Integration is effortless with our plug & play design, compatible with most metallurgical microscopes via USB 2.0 or USB 3.0 ports. Simply connect the camera, install the software, and begin capturing and analyzing images.Q: What image formats and resolution does the software support for capture and analysis?

A: The software supports BMP, JPG, TIF, PNG, and GIF formats and is compatible with HD and Full HD camera inputs, ensuring high-quality image capture and analysis.Q: What benefits do the measurement and annotation tools provide for metallurgical analysis?

A: Measurement tools enable accurate readings of length, area, angle, perimeter, circle, polygon, and ASTM grain size, while annotation tools-such as text, arrows, shapes, and color coding-facilitate detailed documentation and improved clarity in image analysis.Q: When will software updates be made available, and what is the cost?

A: Free updates are provided for one year from the date of purchase, ensuring you receive the latest features and enhancements without any additional cost during the period.Q: Where can the software be used, and what system requirements must be met?

A: The software is suitable for use in industrial laboratories, educational institutions, and research centers. Minimum requirements include an Intel Core i3 processor, 4GB RAM, and 500MB free disk space on Windows 7/8/10 (32/64-bit) systems.Q: What is the process for exporting reports and sharing results?

A: Automatic report export functions enable direct saving and sharing via Excel, Word, and PDF. You can also print or email reports for convenient documentation and communication of findings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free